#FarmLove – Turner Hill Malting Company

Darrell Turner was living the city life and doing very well in his career as a mechanical engineer when he and his wife, an architect, decided to step off the treadmill. After a trip around the country, they returned to the Turner family dairy farm in western Massachusetts to plot the next step. That move, it turned out, was not to move—and Darrell became the fourth generation on the farm.

While he is plenty busy helping his father and uncle manage the 120-head dairy herd, 600 acres of crops and custom harvesting work for other area farms, Darrell has also launched a separate business in a storage shed behind his grandparents’ house, where he and his wife now live.

At dawn, Darrell and his dad do morning milking, symbolic of a nice, tall glass of milk to get the day off to a strong start. Then, with his new Turner Hill Malting Company, Darrell contributes to a different fresh, local beverage that helps people wind down at the other end of a long day.

Turner Hill Malting Company produces malted barley to sell to small brewers in the Berkshires. “The local scene is really hot here. Anything that says local on it sells like hotcakes,” Darrell explains. “There are a bunch of microbreweries around here and they’re trying to source ingredients locally where they can.”

As far as Darrell knows, his is only the second malt house established in the entire state of Massachusetts. “It’s near-impossible to get any local malt,” he says. “I saw it as a pretty enormous opportunity.” On the flip side, now that he’s up and running, Darrell acknowledges with a chuckle, “I know why nobody does this. Ultimately, it’s a simple process but it’s time-consuming and I had to build some of my own equipment.”

Bill and Christine Heaton of Big Elm Brewing in Sheffield, Massachusetts were very happy to learn of Darrell’s new business. Malt is a critical beer ingredient, “the base of every beer,” says Bill. It’s essentially germinated, sprouted grain seeds, Bill explains, usually barley, although it could be wheat, rice, sorghum or millet. The malting process converts some of the seeds’ starch into sugar. “When you malt the grain, the flavor just explodes,” Bill says.

Malting is not an easy process, Bill notes; it requires some serious equipment and know-how. “It’s pretty intense stuff,” Bill says, “but Darrell was an engineer out in the real world before he came back to the farm. It’s a good match. The flavors of his malt are great and every batch he does, it gets better and better.”

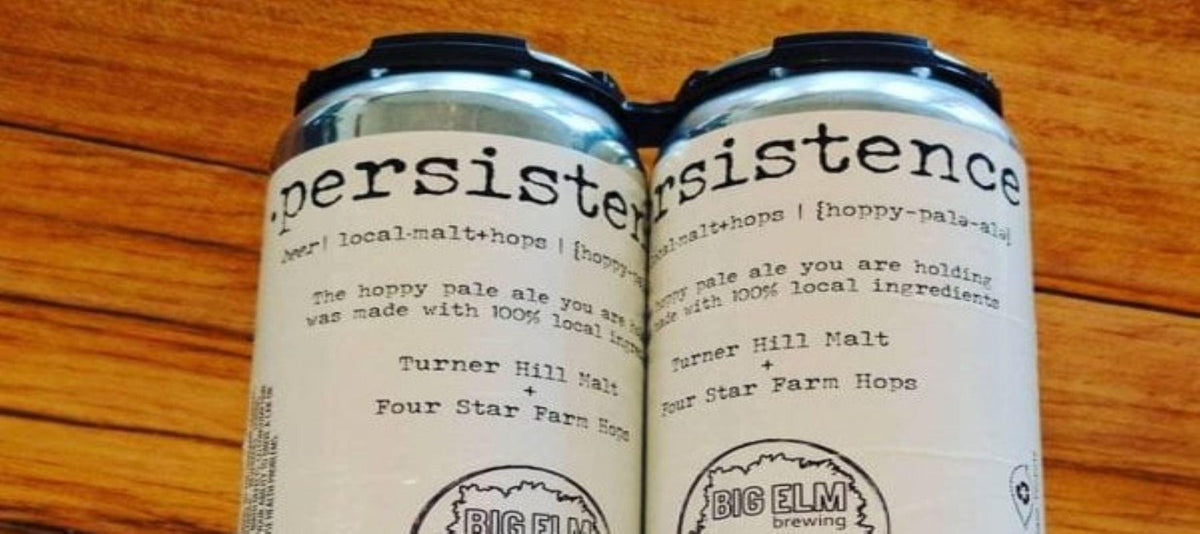

Big Elm featured Turner Hill malt in a batch of a beer they called Persistence that Bill describes as “a nice pale ale made with local malt and local hops.” Persistence, he says, refers to what it takes to “eke out a farming life” these days.

Darrell did develop his new endeavor, he says, with the broader farm business in mind. “We all need to expand or diversify to keep going,” he says. “I feel good that this is still connected to food and agriculture.”

To finance some of the initial capital investment, Turner Hill Malting Company secured a small, zero-collateral loan from Salisbury Bank facilitated by The Carrot Project, which works to provide financing and business resources in support of sustainable local farm and food economies. “It’s incredibly hard to get funding for agriculture and food processing businesses,” Darrell says. “Banks are not that excited about this kind of loan. The Carrot Project was really helpful.”

His mechanical engineering background definitely served Darrell well in the design and construction of his own small-scale malting system. The multi-step process involves steeping the barley until it germinates, drying it down, removing the sprout tails and then a final cleaning of the malted barley. Darrell’s experience in both farming and engineering helped him think outside the box to find solutions where equipment was lacking; he even retrofitted an 1890s seed cleaner for the last step.

Since Turner Hill’s first test run in January, Darrell is up to three batches a month, yielding a total of over 1,000 pounds. He’s had no trouble selling through what he produces and the original 10- by 15-foot storage shed pilot space will soon need expansion. Although he’s currently sourcing barley from Maine, Darrell says that the eventual goal may be to grow his own, but he’d have to be confident that he could achieve consistently high quality, he says.

Nick Whalen, co-owner of Shire Breu-Hous in Dalton, Massachusetts, is another satisfied brewery customer. “We love using Darrell’s malt for a lot of reasons,” Nick says. “He’s the first maltster in the area since Prohibition, which is amazing. And brewing is so closely related to agriculture, the fact that he’s also a local farmer is a beautiful thing.”

Shire Breu-Hous uses Turner Hill malt in their Saison which, Nick explains, “was traditionally what Belgian farmers would produce for their farmworkers. It was typically low-alcohol and safer than water to drink at the time. Every farm would have a different Saison.” In addition, they use the malted barley to sour their Berliner Weiss, he continues: “It gives it a beautiful funk on the nose, kind of like a barnyard funk in a really, really good way with a clean lactic finish.”

The ability to purchase locally malted barley helps Shire put out “a true New England product, something that really represents the taste of our land, our county,” Nick says. “It fits with everything we’re trying to do, not because it’s a cliché but because it’s the right thing to do. It just makes sense.”

For more information on Darrell Turner’s malting operation.

To taste the results of beer brewed with Turner Hill Malting Company product, check out: Shire Breuhous and Big Elm Beer

The Carrot Project works with farm and food businesses in New England and the Hudson Valley supporting their successes by helping them build the financial management skills to help their businesses thrive.